This

article is somewhat personal to me, as I'm currently using a Dell Lattitude

D520 Laptop that gets pretty hot. I know I have to eventually pop her open and

clean the fan as explained in my Geezam blog

article “Tips

and Tricks on how to make your computer run faster” but I'm somewhat of a procrastinator.

So

when I read about a research team from Stanford University that has figured out

a way to miniaturize Fiber Optic Cables to be used inside of a Laptop as

reported in the article

“Breakthrough

brings optical Data transport closer to replacing wires”, published May 28

2015, Physorg, I was beside myself with

excitement.

Their

research, led by Stanford graduate student Alexander Piggott, was published in

Nature Photonics Journal. Again, a lot of PhD’s riding on this wagon, so here's

yet another long list:

1.

Stanford electrical engineer Dr. Jelena

Vuckovic

2.

Graduate student and Google employee

Jesse Lu

3.

Graduate student Jan Petykiewicz

4.

Postdoctoral Stanford student Thomas

Babinec

5.

Postdoctoral Stanford student Konstantinos Lagoudakis

What

their research yielded was a method of creating Fiber Optic Data circuits using

silica glass to replace the copper and gold wires used in the making of

motherboards in laptops and computers. Because they are made from silica glass

and not wires, they are not prone to the heating effect normally seen in your

traditional computer.

Best

of all, silica glass naturally refracts IR (infrared) light, the same frequency

of light that is used by Fiber Optic Data Transmission systems. Thus, if you

could replace the Bus on a computer motherboard, you could eliminate the need

to do optical-to-electrical conversion, at least until you reach the Processor.

So

how did the Stanford research team shrink the tried and trusted Fiber Optics

system that is the basis of modern telecommunications to fit into a computer?

And can this potentially be the

Optical

computer I've long dreamed in my blog

article entitled “IBM

develops 25Gbps Photonic Optical Processor at the 90nm level - IBM's Red Dawn

(2012) for Optical Processors”?

Stanford University

Researcher develop Fiber Optic Motherboard Bus – Cool Running’s for Computers

The

research conducted by the team was actually the continuation of previous work

done by Professor Jelena Vuckovic

with Professor David Miller years prior.

Acting

as a guide to Stanford graduate student Alexander Piggott, her previous

research foray into computers revealed that as much as 80% of the power wastage

in terms of heat loss was not from the Processor but from the motherboards,

quote: “Several years ago, my colleague David Miller carefully analyzed power

consumption in computers, and the results were striking. Up to 80 percent of

the microprocessor power is consumed by sending Data over the wires so called

interconnects”.

“Wow”

was my first reaction reading article, as I'd always assumed it was the Processor

drinking up all that power.

That

idea has been reinforced while at MICO

College University while doing my Diploma in Professional Studies, as I

often have to pop over into the Computer Lab at the e-Learning or at the MICO

University Library. Whenever I use a computer, I notice that the computers make

an awful lot of noise, almost like an airplane about to take off.

I've

always assumed it was the Processor cranking up and needing all that cooling to

keep it functioning, as I've had similar problem with my Gaming rig back home

in Milk River, Clarendon, which is also noisy despite my best attempts at

optimization. However, my computer has a

steady fan noise, not an ever increasing hum akin to an airplane taking off as

I’d observer with computers at MICO

College University, as the fan in my personal PC is rather large.

Up

until now I thought the solution lied in improving the cooling technology used

in computers using liquid cooling techniques, such as UAH's (University of

Alabama in Huntsville)

Fluorinert

FC-72 Passive Cooling System as described in my blog

article entitled “UAH

Graduate Students use 3M's Fluorinert FC-72 in Passive Cooling System – Gaming

Rigs and Data Centers Noiseless Cooling Systemss upgrade”.

More

exotic solutions such as using CNT’s (Carbon Nanotubes) and room temperature superconductors

made from Group 4 Elements as described in my blog

article entitled “@UTAustin

at Austin develops Silicene Transistors - How to grow Silicene and Group 4

Super-conducting Processors and Batteries on Silver Spoon”.

But

they’d still require cooling. A computer Motherboard with the Data Bus based on

Fiber Optics, on the other hand, is inherently cool running as it’s not

electricity heating up copper and gold connectors and traces but IR (Infrared

Light) in silica glass fibers!

Stanford University’s Inverse

Design Algorithm – Microscopic Fiber Optic components for Optical Computer

Their

idea was to replace those copper and gold connectors and traces used in the

Motherboard's Bus to interconnect the various components that the Processor

communicates with silica glass based Fiber Optic cables. Most likely, these

electrical circuit components that process Data i.e. Processors, Memory,

Hard-drive, would sit in or connect via a special socket that does the optical-to-electrical

conversion.

This

would allow the TTL (Transistor-Transistor Logic) and MosFet based processors

and components to work, with capacitors, resistors and inductors still needing basic

electrical connections.

By

replacing the Motherboard Data Bus with a Fiber Optic Network, it makes the computer

run cooler and connect to Fiber Optic Internet the need for optical-to-electrical

conversion. A Fiber Optic Motherboard

Bus also allows you to multiplex more Data into fewer Data pathways, making

such a computer more efficient and powerful to quote Stanford graduate student

Alexander Piggott: “Optical transport uses far less energy than sending

electrons through wires. For chipscale links, light can carry more than 20

times as much Data”.

To

create these Fiber Optic circuits to replace the Motherboard Data Bus, they

created a computer program which they dubbed the Inverse Design Algorithm. It's

basically like a PCB (Printed Circuit Board) software program, similar to those

you can find online.

|

But

their program is more advanced, as it takes into consideration the properties

of silica glass as it relates to its ability to refract IR light to design

circuit analogs to switches, multiplexers and amplifiers, but specifically

geared at manipulating IR light.

Interestingly

too, the circuit it designs are microscopic in scale, with circuits so small

that twenty (20) of them would make up the width of a human hair.

The

PCB diagrams made by the Inverse Design Algorithm are then etched out using

their laboratory fabrication facility, albeit not to a high level of precision

to quote Stanford graduate student Alexander Piggott: “Our manufacturing

processes are not nearly as precise as those at commercial fabrication plants.

The fact that we could build devices this robust on our equipment tells us that

this technology will be easy to massproduce at stateoftheart facilities”.

Because

these structures, made of silica are to be connected to silica glass traces,

most likely they'll be encased in epoxy or some other type of cladding like

traditional Fiber Optic cables used in Telecoms so as to reduce refractive

losses.

Optical Computer with

CNT Processors – Fanless Computers designed by Artificial Intelligence

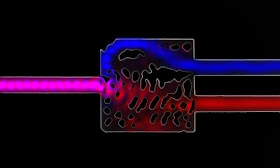

The

designs that the Inverse Design Algorithm comes up with are beautifully and

visually stunning, but are geared towards creating circuits equivalent in

function to their analog counterparts by manipulating the refraction of IR

light, to quote Dr. Jelena Vuckovic: “Our structures look like Swiss cheese but

they work better than anything we've seen before”.

So

it won't be too long before AI (Artificial Intelligent) programs are cooking

our food too as predicted in my blog

article entitled “US$15,000

Moley Robotics Cooking Robot – Cooking Robot seeking Taste for Human Food to

take over in 2017”.

Hopefully,

this all means that the CNT (Carbon Nanbotube) Processor that Standard

University has been working on as far back a September 2013 as described in my blog article

entitled “University

of Stanford Designs a Proof-of-concept Processor using Carbon Nanotubes -

Practical option to expand Moore’s Law along with Optical, Quantum and Neural

Net Processors” now finally has some optical Pathways to efficiently

process Data and interface directly with the Fiber Optic Communications

standards used in Telecommunications today.

The

potential of this breakthrough Inverse Design Algorithm is huge, as it can be

used to design all types of Optical communications systems based on Fiber Optics.

Not only does it eliminates the need to do optical-to-electrical conversion to

connect to Fiber Optic based Internet, at least until you reach the Processor,

but it also makes the computer run cooler, more efficient and potentially

faster!

Inverse

Design Algorithm ties in automation into the design of circuits, which made the

manufacturing of telecommunications gear by Telecom Equiptment suppliers

achieve economy-of-scale much faster by giving the work to machines instead of

humans. If this is how Optical fanless computers will come to pass, then I’m

all for it!

No comments:

Post a Comment

Please register and leave you comments. For contact, leave an email or phone number and I'll be sure to get back to you.